Metals are crucial in building, manufacturing, transport, and other applications. However, exposure to air, water, and chemicals could cause corrosion and corrosion and lead to harm and costly fixing . That is why protecting metal and expanding the time of usage and effectiveness is very crucial. here are the common questions such as: what is metal protection, why is it necessary, what type of coatings are used, etc. in this article.

What is Metal Protection?

Metal protection is methods and processes that avoid corrosion, decay, and rust. It makes it stronger, long-lasting, and durable.

Why We Protect Metals?

Since metals are prone to oxidizing, chemical reaction, and wear, protection helps: Inhibiting rust and corrosion, Acquire and retain knowledge, Lower maintenance expenses Offer safety and reliability

Which Metal is Used for Protection?

Metals like these are usually applied as protective coats. Zinc, for instance, is used in galvanising, and Chromium is used in making Corrosion-resistant stainless steel.

What Is Protecting Metal?

Common methods include: Applying protective coatings, With sprays or paint, Galvanising or plating, Frequent oiling and lubing, Minimising environmental exposure

What are the 4 Processes for Protecting Metal Surfaces?

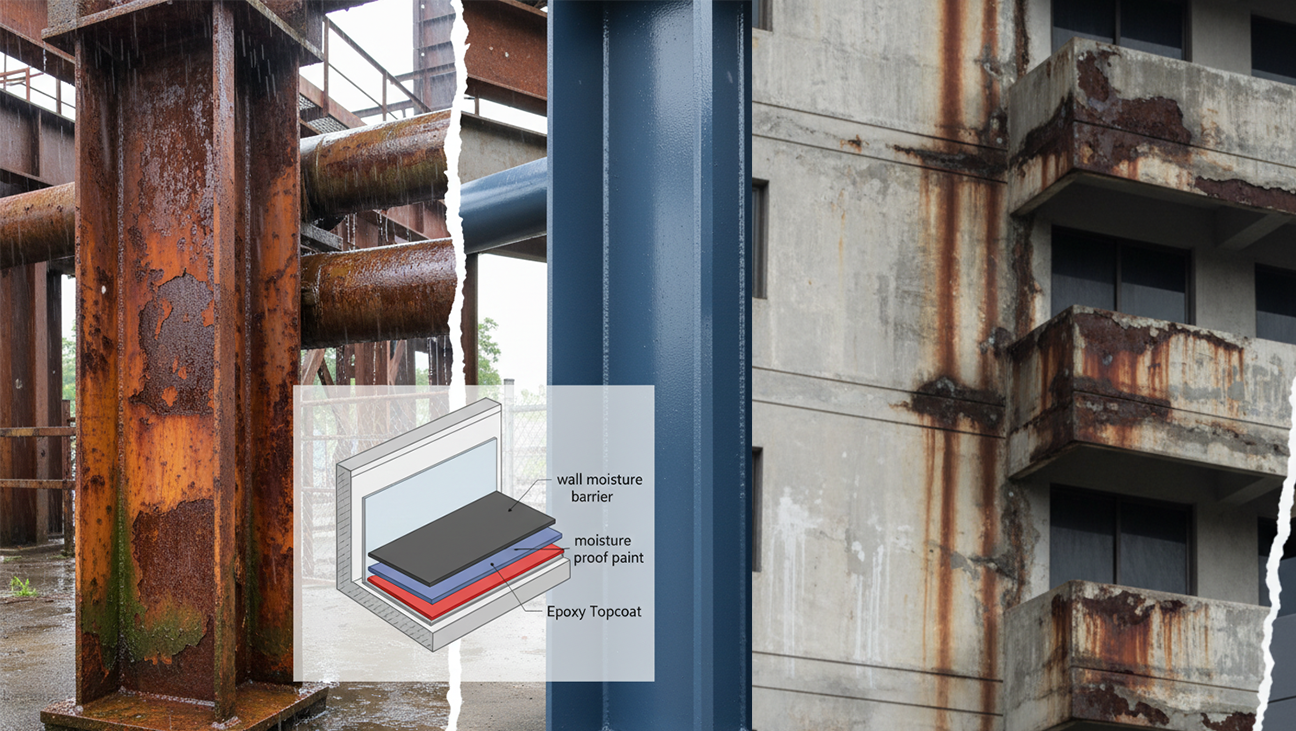

- Coating (paints, epoxy, powder)

- Galvanising (protective zinc layer against rust)

- Plating (nickel, chromium, gold finishes)

- Anodising (aluminium oxide coating)

What are Four Methods of Preventing Metal Corrosion?

- Barrier coatings (paint, varnish)

- Sacrificial coatings (zinc gal)

- Catholic protection (electrical current systems)

- Environmental control (reducing exposure to moisture/chemical)

What are Metal Coating Processes?

- Powder coating

- Electroplating

- Galvanising

- Anodising

- Epoxy paint coating

What are the Types of Metal Coating?

- Epoxy coatings

- Zinc coatings (galvanising)

- Powder coatings

- CERAMIC COAT

- Chrome plating

What is the Best Metal Coating?

It is depending upon usage. To get strength and durability, epoxy coatings and powder coatings are used.

What is the Most Durable Metal Coating?

Powder and epoxy coatings are the strongest and have very good resistance against chemicals, scratches, and corrosion.

What is the Type of Metal Coating?

- Industries typically use:

- Steel galvanising

- Machinery epoxy paint

- Powder painting of furniture and home appliances

- Aesthetics and durability with chrome plating

Which Type of Coating is Best?

Epoxy coatings work best for heavy-duty applications, and powder coatings are for long-lasting coats.

What is the Best protection method for Metal from rust?

Powder-coating coats are strongly suggested for their long lasting, smooth finish and weather-resistant nature.

What is Epoxy Paint for Metal?

It is a hard, chemically-resistant coating that shields metal from moisture, abrasion, and corrosion, and is often used in marine and industrial applications.

What You Coat Metal with for Protection

- Options include:

- Protective oils or greases

- Paints or varnishes

- Epoxy coatings

- Rust inhibitors

Can You Prevent Metal Rusting?

yes but with protective layer to be applied over dry out metal, galvanise it or oil it regularly.

Prevention Methods of Metal-on-Metal Contact?

Mainly used prevention method are lubricants, oils and anti-friction coatings reduce wear.

Does Oil Prevent Metal from Rusting?

Yes. Oil creates a barrier that prevents moisture from acting.

What are Three Methods of Preserving Metals?

- Painting or coating

- Galvanising or plating

- Grease or oil lubrication

What are the Four Methods of Metal Processing?

- Casting

- Forging

- Welding

- Extrusive rolling

What is Galvanising?

Galvanising coats on steel surface with a zinc protective coating that prevents it from rusting. It is most popular and efficient protection techniques.

Conclusion

It is crucial to protect metal in order to enhance its life spine, avoid rust, and ensure safety of buildings. Either galvanising, epoxy painting, powder coating, technique will be selected based upon the type and usage of metal.

At www.nextbc.in, metal protection is our first priority so that your metals are long-lasting, safe and strong.

Thanks

Our Related News

Choosing Aesthetics Over Functionality: A Design Dilemma for Homeowners

When designing your dream home, it’s tempting to prioritize beautiful aesthetics—sleek countertops, statement lighting...

Ignoring Natural Lighting: A Common Oversight in Home Design

When designing a home, every decision—from color palettes to materials—contributes to the space's...

Comment(0)

No Comment Yet! Archite post comment box is empty!

Post Your Comment